Tools

Conversion instruction

Conversion instruction

Introduction

Performing of these instructions by a non-qualified engineer can lead to dangerous situations.

-

The supplier is not responsible for the consequences (the arising of a hazardous situation and/or damage to persons or goods) caused by incorrect performance of these instructions by engineers who are not employees of the supplier. Consequential damage arising through inexpert performance of these instructions is not accepted.

-

This conversion-set consists of original parts. Original parts are tested for suitability and safety during the type approval of the appliance. Frequently performed batch-approvals guarantee the quality of original parts.

-

The supplier recommends, when converting an appliance to another gas type, to have this performed by an engineer of the service department. Contact the supplier to make an appointment with a service engineer.

-

For addresses see the guarantee regulations of the appliance.

With this conversion-set you can convert your gas hob from natural gas (NG) to universal liqified petroleum gas (ULPG). Before you start conversion, check whether your gas hob is genuinely set to natural gas.

|

|

Tools |

||

|---|---|---|---|

|

|

A. Socket spanner |

|

E. Nose pliers |

|

|

B. Screw driver flat blade |

|

F. Open end spanner |

|

|

C. Screw driver Torx |

|

G. Leakage test spray |

|

|

D. Screw driver cross head |

||

Contents of conversion set:

-

Injectors for the burners.

-

Simmer setting screws for the gas taps.

-

Gaskets.

-

Two data labels with the modified gas setting.

-

Fiber rings for enamelled appliances.

-

Silicon sealing plugs.

-

Test point adaptor.

Dismantling

Disconnect the appliance from the power supply before you remove the drip tray! Prevent damage of the worktop. Lay down parts of the appliance on a protected base.

-

Remove the pan supports, burner heads and burner cups. Pull off the control knobs vertically and remove them.

-

Loosen the screws of the mounting brackets at the underside of the appliance.

-

Unscrew the screws that are holding the burners.

-

Lift the drip tray on the back of the appliance, dismount the earth wire (if applicable), and slide the drip tray to the front.

-

Remove the drip tray.

Converting

For verification, you can find the values of the injector and simmer setting screws on the holder of the injectors. The characters of the sets correspond with the characters on the label inside the lower tray of the appliance (upper case characters for injectors and lower case characters for simmer setting screws). The values are also indicated on the injectors and simmer setting screws. See table:

|

Gas |

P |

A |

a |

B |

b |

C |

c |

H1 |

H2 |

h |

Plug |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

ULPG |

2.75 kPa |

0.46 |

0.26 |

0.60 |

0.30 |

0.72 |

0.36 |

0.93 |

0.40 |

0.40 |

✔ |

The following sets can occur:

-

Set ‘A-a’ for simmer burner.

-

Set ‘B-b’ for semi rapid burner.

-

Set ‘C-c’ for rapid burner.

-

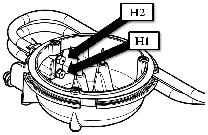

‘H1-h’, ‘H2’ and ‘J-j’ sets for wok burner.

It is possible that not all the injectors in the set will be used for the conversion of your appliance.

-

Replace the injectors in the burners.

Use a socket spanner (7) for disassembling/assembling the injectors in the burners.

-

Replace the simmer setting screws in the taps.

Use a screwdriver, flat-blade 4, for disassembling/assembling of the simmer setting screw and when necessary use pliers.

-

On the wok burner, replace the injectors for outer (H1) and inner (H2) burner using an open end spanner (7).

The injector for the outer burner is the one at the bottom, the upper injector is for the inner burner.

-

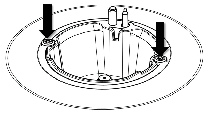

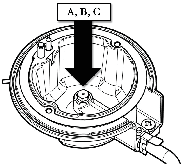

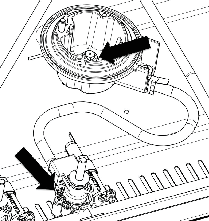

Install the silicon sealing plugs, marked with a letter A, B and C in the air holes of the corresponding burners.

-

If applicable (see table).

Gas

P

A

a

B

b

C

c

H1

H2

h

Plug

ULPG

2.75 kPa

0.46

0.26

0.60

0.30

0.72

0.36

0.93

0.40

0.40

✔

-

-

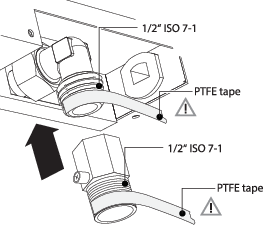

Replace the fitted governor by the test point adapter.

-

Place label “Universal LPG” over the label “Natural gas” at the underside of the appliance and in the cupboard.

Check for gas tightness and operation

When the appliance is connected to the gas supply, use leakage test spray to check the gas tightness.

A. Check leakage of the installation:

-

Open the main gas valve.

-

Check leakage of connections by spraying leakage test spray on the connections and check for gas tightness.

B. Check the leakage of the injectors:

-

Seal the injector.

Press and open tap with thermo electric safety device and keep it pressed down.

-

Spray leakage test spray on the connections and check for gas tightness.

-

Repeat for every burner.

Check the gas tightness with the use of a pressure pump:

-

Connect the pressure pump to the opened testpoint adaptor and close the main gas valve and all gas taps of the appliance.

-

Increase the pressure to 150 mbar and close the tap between the pressure pump and the pressure gauge. Check the pressure. The maximum pressure drop is allowed up to 5 mbar per minute. After checking, open the tap between the pressure pump and the pressure gauge. Open one of the taps and close the corresponding injector.

Press and open a tap with thermo electric safety device and keep it pressed down.

-

Increase the pressure to 150 mbar and again close the tap between the pressure pump and the pressure gauge. Check the pressure. The maximum pressure loss may amount to 5 mbar per minute.

-

Repeat for every burner.

Final assembly

-

Replace gaskets on top of the burners.

-

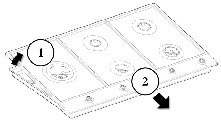

Place the drip tray on the appliance starting with the front side. The hooks on the front of the drip tray must be placed under the edge of the under tray. For enamelled drip trays, do not forget to connect the earth cable to the drip tray.

-

Install the screws around the burner to secure the drip tray. For enamelled drip trays, use new fiber rings under the screws.

-

Tighten the screws of the brackets at the underside of the appliance.

Startup

-

Install the knobs, the burner parts and pan supports.

-

Check whether the appliance is connected to the correct type of gas and gas pressure.

-

Open the main gas valve and insert the plug into the power socket.

-

Check the flame image of the burners. Refer to the 'Checking operation' section at the back of this manual.

Check the correct operation of the burners

Important for this is that:

-

The flame does not smother in simmer rate.

-

The flames are not ‘blowing off’ at maximum rate (recognizable by flames that are far away from the burner in combination with a 'hissing' sound).

-

Check the flame image of the burners. Refer to the 'Checking operation' section at the back of this manual.

Your notes

Checking operation

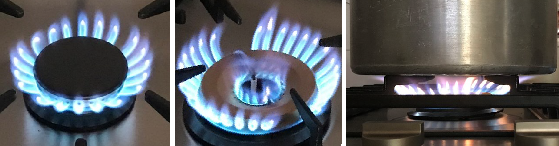

Flame pattern using LPG or Propane gas

Flame pattern using Butane gas

In contrast to propane gas, conversion to butane gas will result in a more yellow flame pattern (yellow tipping). Yellow tipping is customary and safe and has no negative impact on combustion, use etc.